Blow fill seal

Blow Fill Seal (BFS) is an advanced manufacturing technology for aseptic primary packaging of pharmaceutical liquids in plastic containers from 0.2ml to 1000ml.

Starting from the polymer granule, containers are formed, filled and sealed in one continuous operation inside one SYFPAC® BFS machine, within seconds and in an aseptic controlled environment.

The technology

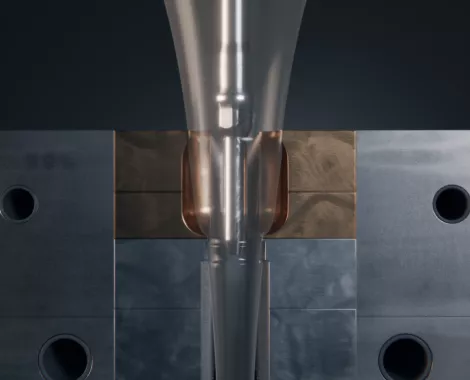

BLOW

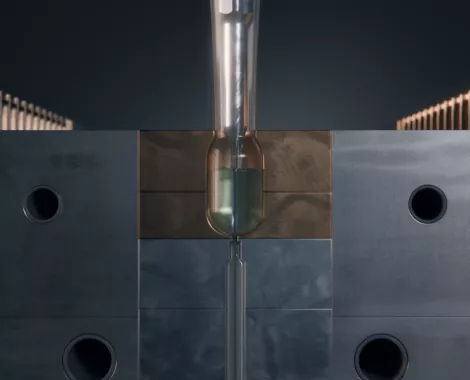

FILL

SEAL

Should I switch to BFS?

SYFPAC® – The advantages

SAFE

FAST AND FLEXIBLE

COST-EFFECTIVE

EASY TO USE

Applications

SYFPAC® Blow Fill Seal machines are designed for production of Small Volume Parenterals in vials, ampoules and prefilled syringes from 0.2 to 50ml (SYFPAC® DUO), as well as Large Volume Parenterals from 50ml to 1000ml (SYFPAC® LVP).

BFS containers are suitable for many applications: vaccines, eye drops (single use or multidose), IV solutions, injectables, WFI, enemas, biologicals, ophtalmics, disinfectants, chemicals, cosmetics and much more.